Abrasive blasting is a technological process in which abrasive material is mixed with high pressure air and the workpiece is sprayed with this jet of particles.

This method is suitable for cleaning corroded surfaces, painting, powder painting and other surface treatments. The quality of the material to be treated determines the maximum blowing speed and the quality and size of the particulate material.

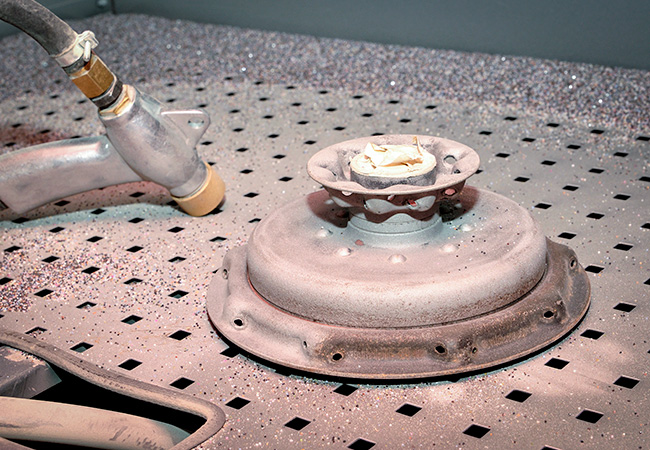

The closed design technology of blasting is mainly used for rust removal, removal of old paint and cleaning. The material of different size workpieces can be metal, wood, plastic, plexiglass, glass or ceramic. By spraying the surface, we can easily remove the contaminants on it, making the surface metal-pure. The metal recovers its original state and colour.

The cleanliness, uniformity and surface roughness of the workpieces prepared by blasting highly influence the durability of the subsequent surface treatment methods.

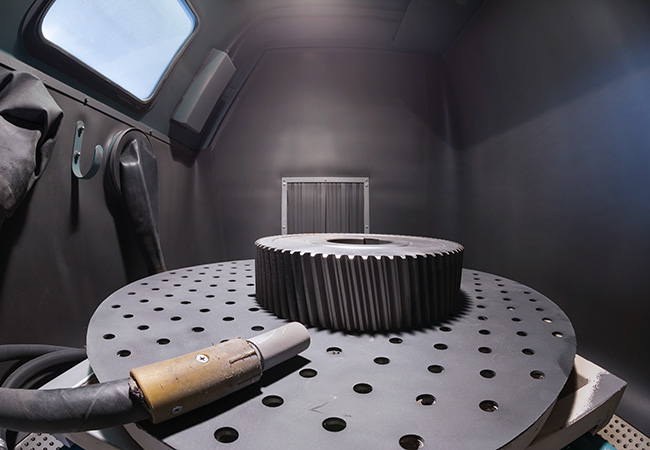

Powder blasting cabinet

The powder blast cabinet operating by our company is one of the most advanced tools in the market. Good quality and value for money is guaranteed not only due to the variety of materials being handled and the range of abrasive materials, but also to the environmentally friendly technology and efficient recycling of the abrasive material.

By blasting technology our equipment is suitable for surface cleaning and the roughening of smaller and larger metal, casting, plastic and even glass products, as well as for homogenizing surfaces.

Corundum, glass beads and metal grains of different sizes, hardness and roughness can be used as blasting material.

The 0.2-0.8 mm material is delivered to the spray gun via a wear-proof rubber hose from the pressurized air reservoir at the bottom of the cabin.

Depending on the diameter of the sprayer, our 300 m³/h air-capacity screw compressors ensure a smooth and clean surface, from really small parts to larger fibers up to 6 m length.

Blast materials

Even the best, most expensive paint or coating cannot provide adequate protection against corrosion if it damages under the coating, from within. Proper surface preparation is at least as important as the coating itself. Many substances can be used as cleaning granules. The material of the granule significantly influences the cleaning speed and the quality of work.

Due to the hardness and the shape of the glass bead, it removes contamination and oxides from the surface without damaging the treated surface itself. The glass does not react chemically with other materials, therefore microspheres do not cause corrosion. Suitable for gentle cleaning of sensitive surfaces (molds, tools, engine parts, turbine wheels) and special treatments such as smoothing, shaping, deburring and surface treatment of non-ferrous metals.

Corundum is a blast material made of alumina. It is extremely hard and the edges are renewed during the streaming process.

Particularly suitable for dirt, rust and paint removal, roughening and polishing removal. Due to its very angular shape and hardness, it has a high abrasive effect on the surface.

Types: steel bristle, steel grain or stainless steel particle.

Metallic abrasives for removing oxide layers, rust, oxidation and dyes from steel.

Stainless steel is used for surface cleaning, preparation, in case of non-ferrous metals, cast pieces, forged pieces and granite, marble.