The manufacturing industry is constantly evolving, and automation has become an essential factor in maintaining competitiveness. Two key technologies that are revolutionizing production: 3D laser cutting and laser welding. These solutions not only increase productivity, but also significantly improve quality and reduce production costs. In this professional article, we present the role of 3D laser cutting and laser cutting in the modern industrial environment.

The most important things to know about 3D laser cutting at a glance

The most important things to know about 3D laser cutting at a glance

What is 3D laser cutting?

3D laser cutting is an advanced material processing technology that in which a concentrated, high-energy laser beam is used to precisely cut or shape the material. During the procedure, the Laser beam It penetrates the workpiece without contact, thus melting or evaporating the material locally, which enables extremely precise cutting operations. The term “3D” refers to the fact that this technology allows not only cutting in the plane, but also the creation of complex, three-dimensional geometric shapes, even along varying angles and curves. As a result, 3D laser cutting is a highly flexible, fast and material-efficient solution in modern industry.

Compared to traditional mechanical cutting technologies, 3D laser cutting offers greater accuracy and flexibility. Main advantages:

- High precision: Achieve accuracy down to micrometers.

- Less material loss: Thin cutting gap and minimal heat exposure reduce deformation.

- Speed and flexibility: One machine can process materials of different thicknesses and types without changing tools.

The most important applications of 3D laser cutting are in the automotive, aerospace, and electronics industries, where the fast and accurate production of complex parts is crucial.

The most important information about laser welding at a glance

What is laser welding?

Laser welding is a welding process that uses a high-energy laser beam to fuse materials together. The laser beam provides a concentrated heat source that allows for precise and fast welding with minimal heat impact on surrounding areas.

Laser welding features:

- High precision – Great for joining thin materials and small parts.

- Fast process – It can weld at high speeds, increasing production efficiency.

- Minimal heat input – Reduces deformation and changes in material structure.

- Automatability – Easy integration with industrial robots and CNC systems.

- Wide range of materials – Suitable for welding steel, aluminum, titanium, copper and other metals, as well as some plastics.

Laser welding techniques:

- Continuous Laser Welding – A continuous laser beam ensures an even seam, ideal for long welds.

- Pulsed Laser Welding – Works with short laser pulses, it is gentler and more precise, ideal for thin materials and micro-welds.

- Keyhole Welding – A high-energy laser beam creates a small-diameter, deep melting zone, resulting in a strong and deep bond.

In what industries is 3D laser cutting and laser welding used?

3D laser cutting and laser welding are used in many industries, especially where precision, speed and automation are key. Below are the key industries:

Automotive industry

Both 3D laser cutting and laser welding play an important role in automotive manufacturing:

3D Laser Cutting:

- Cutting body parts (e.g. doors, roof panels, exhaust systems).

- Precise cutting of light alloys and high-strength steel parts.

Laser welding:

- Fastening engine parts (e.g. cylinder heads, camshafts).

- Battery cell welding for electric vehicles.

- Welding of safety elements such as airbag systems.

Aerospace

In this industry, lightweight but strong materials and maximum precision are essential.

3D Laser Cutting:

- Cutting aircraft structural elements (e.g. titanium alloys and aluminum).

- Cutting out complex shapes and internal stiffening structures.

Laser welding:

- Pinpoint welds on fuel systems and turbine blades.

- Production of rocket engines and heat shields.

Electronics industry

Laser technology is essential for miniaturized components and sensitive materials.

3D Laser Cutting:

- Precise cutting of circuit boards and plastic covers.

- Cutting out fine copper wires and heatsinks.

Laser welding:

- Micro soldering in the manufacture of batteries and electronic connectors.

- Capture screen panels in smart devices.

Medical technology

In the production of surgical and implant devices, sterility and precision are of paramount importance.

3D Laser Cutting:

- Custom cutting of titanium implants and prostheses.

- Shaping precision surgical instruments.

Laser welding:

- Attachment of medical instruments (e.g. catheters, endoscopes).

- Welding pacemakers and other implants.

Mechanical engineering and metal industry

It is often used for the unique design and fast production of machine parts.

3D Laser Cutting:

- Cutting high-precision metal parts.

- Optimization of custom prototypes and series production.

Laser welding:

- Assembly of steel structures.

- Reinforcement of hydraulic and pneumatic system connections.

Jewelry and luxury goods manufacturing

For the fine machining of jewelry and precious metals, laser cutting and laser welding are the perfect choices.

3D Laser Cutting:

- Cutting out unique designs in gold, silver and platinum.

- Decoration of watch parts and fine jewelry.

Laser welding:

- Soldering jewelry together without damaging the gemstone.

- Small, precise fastenings and unique shapes.

Furniture and design industry

Laser technology is also advantageous in the production of modern furniture and unique interior design elements.

3D Laser Cutting:

- Precise cutting of metal and wooden elements.

- Creating custom patterns and perforations

Laserwelding:

- Fastening steel and aluminum structures.

- Fine fitting of decorative and art objects.

Military industry

Arms production and ammunition production

3D Laser Cutting:

- Cutting precision weapon parts (e.g. barrels, breeches, sights).

- Production of lightweight and reinforced weapon parts from titanium, steel or other special alloys.

Laser welding:

- Precise and fast welding of ammunition (e.g. cartridge casings and explosive device covers).

- Assembly of sensitive electronic components for military drones and autonomous weapon systems.

What should you pay attention to as a customer if you want to entrust a company with 3D laser cutting and laser welding?

If you want to entrust a company with 3D laser cutting and laser welding, it is worth considering the following aspects as a customer:

Technology background and expertise

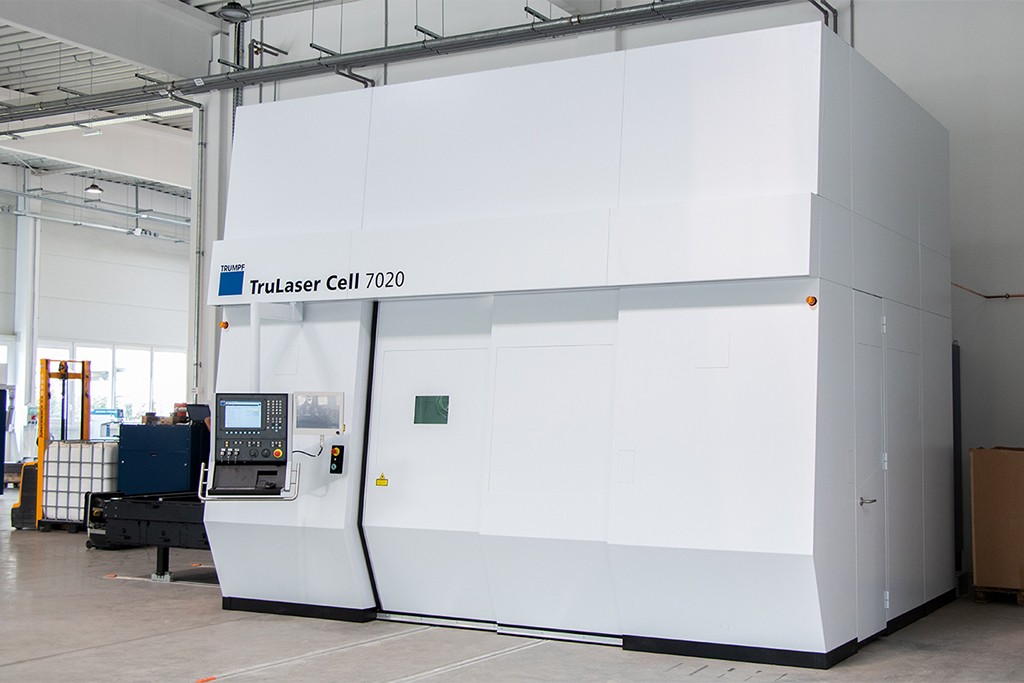

- Make sure that the company has the necessary modern equipment and experience.

- What types of materials can they cut and weld? (steel, aluminum, stainless steel, etc.)

- Ensuring sufficient precision and cutting quality (e.g. ±0.1 mm accuracy).

- Do you have experience in working with more complex geometric shapes?

References and quality assurance

- Take a look at the company’s previous work, or ask for references or samples.

- Do they have ISO 9001 or other quality assurance certificates?

- Do they have an internal quality control process, such as geometry inspection or material testing?

Production capacity and deadlines

- Can you handle the expected production volume (individual pieces or serial production)?

- What is the agreed production and delivery time? (Scheduling is important!)

- Are you flexible about subsequent changes?

Costs and request for quotation

Ask for a detailed quote, which includes:

- Cutting and welding costs.

- Any design or programming fees.

- Shipping and other additional costs.

It is worth comparing several offers to get the best value for money.

IMPORTANT NOTE: The cheapest quote is not always the best!

Communication and collaboration

- How fast and efficiently do the company’s employees communicate?

- Can they help with planning and optimization (e.g. recommending more cost-effective solutions)?

- Is there an opportunity for a personal consultation or a plant visit?

Concluding thoughts

3D laser cutting and laser welding are not only technological innovations, but also driving the modern industrial revolution. These innovative solutions enable production processes to be carried out faster, more accurately and more economically, helping to maintain competitiveness and continuously improve quality. The key to the industry of the future lies in the fact that companies today recognize the strategic benefits of automation: reduced material loss, consistent quality and a safer working environment all contribute to success.

Overall, the decision to invest in state-of-the-art technologies not only responds to today’s challenges, but also ensures the industry-leading role of the future. The integration of precision machining and automated processes is the embodiment of the principles of Industry 4.0, which is already shaping tomorrow’s production today. One thing is clear: a commitment to technological progress is the key to tomorrow’s success.

If you need a professional partner who is able to tasks in addition to laser cutting, laser welding, robotic welding tasks, then feel free to contact us. With the help of our serious machine park, we are able to complete all tasks on time, all in excellent quality.